Analysis and Design of Two-way Slab System

(Two-Way Slabs Supported on Stiff Beams or Walls)

Moment

Coefficient Method

Bangladesh

National Building Code (BNBC-2020)

6.5.8.2

Scope and limitations:

6.5.8.2.1

The provisions of this section may be used as alternative to those of Sections

6.5.1 to 6.5.7 for two-way slabs supported on all four edges by walls, steel

beams or monolithic concrete beams having a total depth not less than 3 times

the slab thickness.

6.5.8.2.2

Panels shall be rectangular with a longer to shorter center to center support

span ratio of not greater than 2.

6.5.8.2.3

The value of

Steps

in Moment Coefficient Method

Step 01: panel/slab case determination from cases (From

Code, given at the end)

Step 02: Determination of thickness of the slab

panel,

hmin = perimeter/ 180 = 2(la + lb)/180

Step 03: Calculation of factored loads on slab

Step 04: Calculation of m = la/ lb

Step 05: Determination of moment coefficients from

tables.

Step 06: Calculation of moments and then design.

Step 07: Apply reinforcement requirements.

Step 07: Shear check.

Calculation of moments

Example:

·

Live Load = 45 psf

·

fc′= 3 ksi

·

fy = 60 ksi

· super dead load = 0.02 ksf

Step 01: panel/slab case determination from cases

Two adjacent edges discontinuous, hence case = 4

Step 02: Determination of thickness of the slab panel

hmin

= perimeter/ 180 = 2(la + lb)/180 = 2(18+20)/180 = 0.422*12

Step 03: Calculation of factored loads on slab

Total dead

load = 5.5/12*0.150 +0.02=0.089 ksf

Live load =

45 psf = 0.045 ksf

Factored

dead load, wu dl = 1.2*0.089=0.11 ksf

Factored

live load, wu ll = 1.6*0.045=0.072 ksf

Total factored load, wu =0.11+0.072=0.182 ksf

Step 04: Calculation of m = la/ lb

m = la/ lb = 18/20=0.9

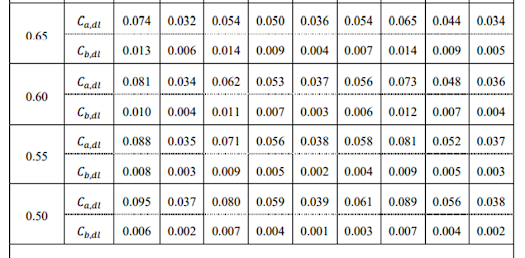

Step 05: Determination of moment coefficients from tables (Provided at the end)

Ca,neg = 0.060 (BNBC-Table 6.6.8)

Cb,neg = 0.040 (BNBC-Table 6.6.8)

Ca,pos,dl =0.033 (BNBC-Table 6.6.9)

Cb,pos,dl = 0.022 (BNBC-Table 6.6.9)

Ca,pos,ll = 0.039 (BNBC-Table 6.6.10)

Cb,pos,ll = 0.026 (BNBC-Table 6.6.10)

Step 06: Calculation of moments and then design

|

Ma,neg

= |

Ca,neg * Wu * la2 |

0.060*0.182*182 |

= 3.54 |

3.54 |

|

Mb,neg

= |

Cb,neg * Wu * lb2 |

0.040*0.182 *202 |

= 2.91 |

2.91 |

|

Ma,pos

= |

Ca,

pos, dl * Wu, dl * la2 |

0.033*0.11*182 |

= 1.18 |

1.70 |

|

Ca,

pos, ll * Wu, ll * la2 |

0.022*0.072*182 |

= 0.51 |

||

|

Mb,pos

= |

Cb,

pos, dl * Wu, dl * lb2 |

0.039*0.11*202 |

= 1.72 |

2.46 |

|

Cb,

pos, ll * Wu, ll * lb2 |

0.026*0.072*202 |

= 0.74 |

Step

07: Apply reinforcement requirements

Consider 12 inch width of strip, b=12 inch

davg = 5.5 - 0.75- 0.375 (#3) = 4.375

|

|

Ma,neg |

Mb,neg |

Ma,pos |

Mb,pos |

|

3.54 |

2.91 |

1.70 |

2.46 |

|

|

|

0.072 |

0.058 |

0.034 |

0.049 |

|

As

, in2 |

0.20 |

0.15 |

0.089 |

0.13 |

|

As

, in2 , min (0.0018*b*h) |

0.12 |

0.12 |

0.12 |

0.12 |

|

Spacing,

S ≤2h

&18’’ |

(Area

of used bar*12)/Total Area of Bars (as × 12)/(As) = 6’’

c/c < 2*5.5=11 &18’’ |

8’’

c/c |

11’’

c/c |

10’’

c/c |

Step

07: Shear check

Wa = 0.60 (BNBC-Table 6.6.11)

Wb = 0.40 (BNBC-Table 6.6.11)

W La (Ult) =

0.60*0.182 = 0.11 kip/ft

W Lb (Ult) =

0.40*0.182 = 0.07 kip/ft

vuLa = 0.11*[(18/2)-(4.375/12)] = 0.95 [vuLa =W La

(Ult) *( La/2

– d)]

vuLb = 0.07*[(20/2)-(4.375/12)] = 0.67 [vuLb =W Lb(Ult)

*( Lb/2

– d)]

ØVc =

0.75(2

Vu = maximum of vuLa and vuLb

Hence, ØVc

≥ Vu , ok.

BNBC- Tables