Experiment No: 07

Determination of Time of Setting of Hydraulic Cement by

Vicat Needle

Introduction

The determination of the setting time of hydraulic cement is a critical procedure in the construction industry. Setting time refers to the period required for cement to transition from a fluid or plastic state to a solid state. This characteristic influences the handling, finishing, and curing processes in concrete construction.

The term setting refers to the

solidification of the plastic cement paste. The beginning of solidification,

called the initial set, marks the point in time when the paste

has become unworkable. Accordingly, concrete placement, compaction, and

finishing operations are difficult beyond this stage. The paste does not solidify

suddenly; it requires considerable time to become fully rigid. The time taken

to solidify completely marks the final set, which should not be

too long in order to avoid delays in the construction process. Almost

universally, the initial and the final setting times are determined by the

Vicat apparatus, which measures the resistance of a cement paste of a standard

consistency to the penetration of a needle under a total load of 300 g. The initial

set can be described as the time in the setting process when the needle

penetrates a 40-mm-deep cement paste until a 25 mm of

penetration is achieved.

The final set is said to be reached when the needle makes an

impression on the surface of the paste but does not penetrate. ASTM C 150, Standard

Specification for Portland Cement, requires the initial setting time to

be not less than 45 min, and the final setting time to be not more than 375

min, as determined by the Vicat Needle (ASTM C 191).

ASTM C191 outlines the standard test method using the Vicat

Needle apparatus, ensuring consistency and reliability in assessing the time of

setting for hydraulic cement.

Scope

These test methods determine the time of setting of hydraulic

cement by means of the Vicat needle. This test method is applicable to all

types of hydraulic cements, including Portland cement, blended cements, and

other cementitious materials used in concrete. The method determines both the

initial and final setting times using the Vicat Needle apparatus, ensuring

compliance with industry standards.

Purpose

The primary purpose of this test is to determine the initial

and final setting times of hydraulic cement. This information is essential for

understanding the workability and timing requirements of cement in construction

applications. The setting time can impact the timing of formwork removal, the

application of subsequent layers, and the overall construction schedule.

ASTM Designation

ASTM C191— Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle.

Terminology

Hydration

The chemical reaction between hydraulic cement and water

forming new compounds most of which have strength-producing properties.

Hydraulic cement

A

cement that sets and hardens by chemical reaction with water and is capable of

doing so under water.

Portland cement

A hydraulic cement produced by pulverizing clinker, consisting

essentially of crystalline hydraulic calcium silicates, and usually containing

one or more of the following: water, calcium sulfate, up to 5 % limestone, and

processing additions.

Normal

consistency

A degree of plasticity

of a hydraulic cement paste that is appropriate for testing as measured by a

stipulated method.

Initial

and Final setting time

The time at which the

cement paste loses its plasticity is termed initial setting time. The time

taken to reach the stage when the paste becomes a hard mass is known as final

setting time.

Significance and Use

This test method determines compliance with a specified

limit for Vicat time of setting. It should be used in mixture with the

appropriate cement specification. However, this procedure may not provide the

same results as other methods for hydraulic cement paste or mortar or concrete

setting.

Determining the setting time of hydraulic cement is vital

for ensuring the material meets the required performance criteria in

construction. The setting time affects the scheduling of construction

activities, such as the removal of formwork, the application of finishes, and

the timing of curing processes. Accurate determination of setting time ensures

that the cement performs as expected under specific environmental conditions

and helps in preventing issues related to premature cracking, insufficient curing,

or delayed construction activities.

Apparatus

Reference Masses:

The

physical testing methods for hydraulic cement and related materials must

conform to Class 6 reference masses in Specification ASTM E617. Values from

Table 1 of Specification ASTM E617 for Class 6 metric reference masses:

TABLE 1 Tolerances for Reference Masses

|

Mass, g |

Acceptance Tolerance, ±mg |

Maintenance Tolerance, ±mg |

|

10000 |

1000 |

2000 |

|

5000 |

500 |

1000 |

|

3000 |

300 |

600 |

|

2000 |

200 |

400 |

|

1000 |

100 |

200 |

|

500 |

50 |

100 |

|

300 |

30 |

60 |

|

200 |

20 |

40 |

|

100 |

10 |

20 |

|

50 |

7 |

14 |

|

30 |

5 |

10 |

|

20 |

3 |

6 |

|

10 |

2 |

4 |

|

5 |

2 |

4 |

|

3 |

2 |

4 |

|

2 |

2 |

4 |

|

1 |

2 |

4 |

Scales and

Balances:

The

maintenance tolerance for a mass determination device should not exceed 0.05%

of the test load throughout the test load range. The mass determination devices

with a capacity that exceeds 1000 g must have a readability of no more than 0.1

g. The index scale of a mass determination device with a capacity of 1000 g or

less must be readable up to 0.01 g.

Glass Graduates:

200 mL or 250 mL capacity, and conforming

to the Specification ASTM C1005.

Flat

Trowel:

Having a sharpened

straight-edged steel blade 100 mm to 150 mm in length.

Plane

Non-Adsorptive Plate:

100 ± 5 mm square of similar

planeness, corrosivity, and absorptivity to that of glass (Fig.1, H).

Conical

Ring:

Made of a rigid, non-corroding,

nonabsorbent material and having a height of 40 ± 1 mm, an inside diameter at

the bottom of 70 ± 3 mm, and an inside diameter at the top of 60 ± 3 mm (Fig.1,

G).

Vicat Apparatus:

The Vicat apparatus for this test method shall have a movable rod, B, of mass 300 ± 0.5 g. The end of the rod used for measuring penetration shall have a straight steel removable needle with a diameter of 1.00 ± 0.05 mm and length no less than 50 mm. The needle end that contacts the specimen shall be flat, plane, and at right angles to the axis of the rod.

Figure

1: Vicat

Apparatus

Temperature and

Humidity

·

The temperature of the

air in the vicinity of the mixing slab, molds, and base plates shall be

maintained at 23.0 ± 4.0 °C and at a relative humidity of not less than 50 %.

·

The temperature of the

mixing water used to prepare cement paste and mortar specimens shall be 23.0 ± 2.0

°C.

·

Except during those

times when specimens are being placed into or removed from storage, maintain

the atmosphere in a moist cabinet or moist room at a temperature of 23.0 ± 2.0

°C and a relative humidity of not less than 95 %.

Procedure: Manual

Vicat Apparatus

Preparation of

Cement Paste

·

Mix 650 g of cement with a measured

quantity of water.

·

Measure the water required based on the

percentage of mixing water required for normal consistency.

·

Place the weighed cement in a mixing

bowl.

·

Add the measured amount of water and

mix thoroughly to form a uniform paste. Ensure the mixing time is sufficient to

achieve a homogeneous mixture.

v

For mechanical mixing follow ASTM C305.

v For using reagent water

follow specification ASTM D1193.

Molding Test

Specimen

I.

Quickly form the cement paste into

the approximate shape of a ball with gloved hands.

II.

Then toss six times through a free

path of about 150 mm from one hand to another so as to produce a nearly

spherical mass that may be easily inserted into the Vicat ring with a minimum

amount of additional manipulation.

III.

Press the ball, resting in the palm

of one hand, into the larger end of the conical ring G, Fig. 1, held in

the other hand, completely filling the ring with paste.

IV.

Remove the excess at the larger end

by a single movement of the palm of the hand.

V.

Place the ring on its larger end on

the base plate H, and slice off the excess paste at the smaller end at

the top of the ring by a single oblique stroke of a sharp-edged trowel held at

a slight angle with the top of the ring, and smooth the top, if necessary, with

a few light touches of the pointed end of the trowel.

VI.

During these operations of cutting

and smoothing, take care not to compress the paste.

VII.

Immediately after molding, place the

test specimen in the moist cabinet or moist room and allow it to remain there

except when penetration measurements are being made.

VIII.

The specimen shall remain in the

conical mold, supported by the non-absorptive plate throughout the test period.

Time

of Setting Determination:

i. Allow the time of setting specimen to remain in the moist cabinet or moist room for 30 min after molding without being disturbed.

ii. Determine the penetration of the 1 mm needle at this time and every 15 min thereafter (every 10 min for Type III cements) until a penetration of 25 mm or less is obtained.

iii. Perform the penetration test by lowering the needle D of the rod B until it rests on the surface of the cement paste.

iv. Tighten the setscrew, E, and set the indicator, F, at the upper end of the scale, or take an initial reading. Release the rod quickly by releasing the set screw, E, and allow the needle to settle for 30 s; then take the reading to determine the penetration.

v. At the option of the tester, if the paste is obviously quite soft on the early readings, retard the fall of the rod to avoid bending the 1 mm needle, but when actual penetration measurements to determine the time of setting are made, release the rod only by the setscrew.

vi. Make each penetration test at least 5 mm away from any previous penetration and at least 10 mm away from the inner side of the mold. Record the results of all penetration tests and, by interpolation, determine the time when a penetration of 25 mm is obtained.

vii. The elapsed time between the initial contact of cement and water and the penetration of 25 mm is the Vicat time of setting or Vicat initial time of setting.

viii. Determine the Vicat final time of setting end point to be the first penetration measurement that does not mark the specimen surface with a complete circular impression. [By the needle with an annular attachment]

ix. Verify final set by performing two additional penetration measurements on different areas of the specimen surface.

x. Obtain verification measurements within 90 s of the first “final set” measurement.

xi.

The

elapsed time between the initial contact of cement and water and the end point

determination above is the Vicat final time of setting.

Precautions

·

Keep

all the apparatus free from vibration during the penetration test.

·

Keep

the 1 mm needle straight and clean.

·

The

needle must be kept clean to prevent cement from adhering to the sides of the

needle and decreasing penetration, and to prevent cement from adhering to the

point and increasing penetration.

Calculation

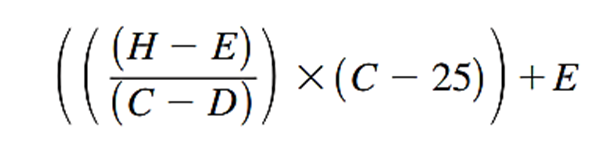

Calculate the Vicat

time of setting to the nearest 1 min as follows:

where:

E = time in minutes of last penetration greater than 25 mm,

H = time in minutes of first penetration less than 25 mm,

C = penetration reading at time E, and

D = penetration reading at time H.

·

Calculate

the Vicat final time of setting by determining the elapsed time

between the time of the initial contact between cement and water and the time

when the Vicat final time of setting end-point is determined, rounded to the

nearest 5 min.

Report

Report the time of

setting using Manual Vicat Needle Apparatus method as follows:

Vicat time of setting (A or B) ______ min

Vicat final time of setting (A or B) ______ min

LAB Assignment Questions:

Basic Understanding

1. What

is the significance of determining the setting time of hydraulic cement?

2. What

is the difference between the initial and final setting time of cement?

3. Why

is the Vicat apparatus used for determining the setting time of cement?

Procedure and Equipment

4. Can

you describe the procedure for determining the initial and final setting time

using the Vicat needle?

5. What

are the components of the Vicat apparatus?

6. How

do you prepare the cement paste for the setting time test?

7. What

is the importance of maintaining a constant temperature and humidity during the

test?

8. What

is the purpose of using the initial and final setting time needles in the Vicat

apparatus?

Calculation and Interpretation

9. How

do you determine the initial setting time using the Vicat needle?

10. How

do you determine the final setting time using the Vicat needle?

11. What

is the significance of the penetration depth in determining the setting time?

12. What

would you infer if the cement paste sets too quickly or too slowly?

13. How

does the water-cement ratio affect the setting time?

Standards and Specifications

14. Which

standards (e.g., ASTM, IS) are followed for determining the setting time of

hydraulic cement?

15. What

are the standard values for the initial and final setting times of Ordinary

Portland Cement (OPC)?

16. Why

is it important to conduct the test at a standard temperature (e.g., 27°C or

20°C)?

17. What

are the acceptable limits of initial and final setting times for different

types of cement?

Application and Practical Considerations

18. How

does the setting time of cement influence the construction process?

19. What

could be the reasons for abnormal setting times, and how can they be corrected?

20. How

does the setting time affect the workability and strength of concrete?

21. What

precautions should be taken while conducting the setting time test with the

Vicat needle?

22. How

can the setting time of cement be controlled in practical applications?

References

ASTM C191 Standard Test

Methods for Time of Setting of Hydraulic Cement by Vicat Needle.