Introduction to Engineering Drawing

Updated on 10-08-2025

Drawing

A drawing is a graphical representation of an object, or a part of it, and is the result of creative thought by an artist, engineer or technician. Drawing is the process of representing objects, concepts, or ideas visually on a surface using lines, shapes, and symbols. It is an essential form of communication in art, design, and engineering. Drawings can be freehand, detailed, or technical, depending on their purpose.

Types of Drawings

Artistic Drawing:

Artistic drawings can

vary widely, ranging from simple line sketches to world-renowned paintings.

This type of drawing serves as a medium for artists to convey emotions,

beliefs, philosophies, and creative ideas.

Engineering / Technical Drawing

An engineering drawing is

a type of technical drawing that is used to convey information about an object.

An engineering drawing is

a technical document that communicates specific information about objects, or

structures. It uses standardized symbols, notations, and scales to represent

details precisely.

Engineering drawing is a

graphical language used by engineers and technical personnel to accurately

represent three-dimensional objects. It is a two-dimensional representation of

a real or imaginary object using graphics, symbols, letters, and numbers, using

engineering drawing instruments.

• Drawing

is the language of engineers. An engineer must be well conversant with

drawings.

• Drawing

represents the reduce shape of the structures and owner visualizes what

is going to be happen.

• Drawing

provides instructions and guidance to architects, engineers and workmen at

field to construct the structure according to the dimension shown in the

drawings.

Engineering Drawing

§ Freehand

Sketch

§ Instrumental

Drawing

§ Computer

aided drawing

Key elements of an engineering drawing include

1. Geometry:

The shape and size of the object or system.

2. Dimensions:

Exact measurements of the components and overall structure.

3. Annotations:

Notes and labels providing additional information.

4. Views:

Different perspectives (e.g., top, side, front) to give a complete

understanding of the object.

5. Scale:

The ratio of the drawing's size to the actual size of the object.

6. Tolerance:

Allowable variations in dimensions.

7. Material

Specifications: Information on the materials to be used.

8. Standards:

Adherence to industry standards for symbols, notations, and drawing conventions

Requirements of Good Drawings

• It

should be simple, clear and clean.

• It

should give exact information so that work can be carried out at site

without scaling for missing measurement.

• Notes

on

the drawing should be held in the minimum to support the drawing.

• Ample

space should be provided between views to permit placing of

dimensions without crowding.

• All

secondary lines should be light & all the primary line should be dark.

Significance of Engineering Drawing

Engineering drawing is crucial because:

·

It serves as a universal language in

engineering and design.

·

It ensures accuracy and reduces errors in

manufacturing and construction.

·

It aids in visualization and facilitates

quality control.

·

Clear and precise drawings reduce

misunderstandings, revisions, and delays, thereby saving time and money.

Drawing Instruments

Developing proficiency in

engineering drawing requires familiarity with drawing tools and their usage

approaches. Selecting the right drawing instruments is crucial to easily

acquiring the required accuracy. The following is a list of typical drawing tools

and accessories:

|

1.

Drawing board

|

|

|

2. Mini drafter

(A small drafter facilitates the drawing of horizontal, vertical, or inclined

parallel lines of specified lengths on the drawing sheet with significant

absence of difficulty or effort) |

|

|

3.

Drawing sheet |

|

|

4.

Drawing Pencil |

|

|

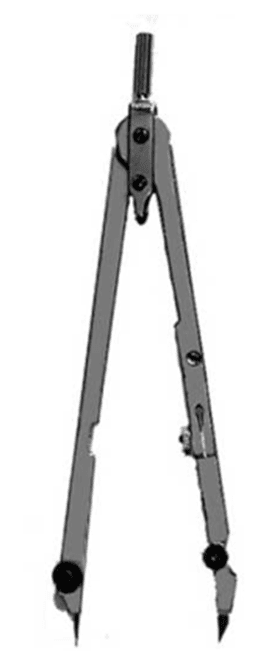

5.

Compass |

|

|

6.

Divider |

|

|

7. Protractor (A

protractor is utilized to construct and define angles, as well as to divide

circles or sectors into a specified number of equal segments. They are

available in semi-circular and circular shapes) |

|

|

8.

Ruler (scale) |

|

|

9. French curves

(French curves are used to draw smooth curves of almost any desired curvature

in mechanical drawings) |

|

|

10.

Set squares |

|

|

11.

Eraser or rubber |

|

|

12.

Sheet fasteners ·

Drawing pins ·

Drawing clips ·

Adhesive tape |

|

|

13.

Template |

|

|

14.

Pencil cutter |

|

|

15.

Sand paper pad |

A sand paper pad or block is used to sharpen the pencil lead. |

|

16.

Brush or towel cloth |

The brush,

duster or towel cloth is used to keep the drawing surface clean |

|

17.

T-Square |

|

|

18.

Anti-Cutter |

|

Keeping the Drawing Sheet

Drawing sheet sizes

Key Points of the System [Main series

(ISO-A series)]:

1.

Halving Principle:

Each paper size is obtained by dividing the size above it in half, parallel

to the shorter side.

o Example:

A1 is half of A0, A2 is half of A1, and so on.

2.

Aspect Ratio:

All sizes maintain the same aspect ratio of 1 : √2 (approximately

1:1.414). This ensures that:

o When

a sheet is folded in half, the proportions remain the same.

3.

Area Ratio:

The area of one size is half the area of the previous size, meaning:

o A0

: A1 = 2 : 1

o A1

: A2 = 2 : 1

o And

so on.

This requirement, gives the following equation for the

sides x and y of a given size

x : y = 1 : √2 = 1 : 1.414

The basic size of the A series, A0, is

defined to have an area of exactly 1 square meter (1 m²). This leads to

the fundamental equation:

x × y = 1 m2

Where:

- x

= shorter side of the A0 paper

- y

= longer side of the A0 paper

- Aspect

ratio must always be: x : y = 1 : √2

The dimension of A0 using this information

Drawing sheet sizes

Drawing Scale

It is not always

realistic to draw the actual object at its true scale on a drawing sheet. For

instance, when illustrating a building on a sheet, one must proportionately

reduce its actual dimensions by an appropriate factor to ensure it fits inside

the confines of the sheet. But if we have to draw a part of a clock into a

sheet, we need to increase its real size by a reasonable factor. The ratio by

which we decrease or enlarge the actual dimensions of the object in the drawing

is referred to as scale.

Scale is

a ratio between the linear dimension of an element of an object shown in

the drawing to the real linear dimension of the same element of the object.

The following are the scales used in

engineering drawings:

Full-Size Scale:

When a drawing is

prepared to the actual size of the object, the scale is said to be full size

scale and the drawing is said to be full size drawing. It is specified by

1:1. It means 1 unit of the drawing is equal to 1 unit of the real size.

Reduction scale:

When a drawing is

prepared smaller than the actual size of the object, the scale is said to be

reduction scale and the drawing is said to be reduce sized drawing. The commonly used reducing scales are

1:2, 1:5, 1:10, 1:20, 1:50, 1:100, etc. The scale specified by 1:2 means 1

unit of drawing is equal to 2 units of the real size.

Enlargement scale:

When the drawing is

prepared larger than the actual size, the scale is said to be an enlargement

scale and the drawing is said to be enlarge sized drawing. The commonly used

enlarging scales are 2:1, 5:1, 10:1 etc. The scale specified by 2:1 means 2

units of drawing is equal to 1 unit of the real size.