Lines and Dimensioning

Lines

Drafting is a graphic

language that uses lines, symbols, and text to describe how to manufacture or

construct a product. Line conventions provide a way to classify the content of

a drawing to enhance readability.

Engineering drawings are

prepared with the help of symbolic lines. In technical drawing and art, a line

is a fundamental element that connects two points and represents the simplest

form of graphical representation. It can define the shape, form, and edges of

objects and can communicate various visual concepts depending on its type,

thickness, and orientation.

Understanding lines is

crucial in drafting, design, and artistic practices because lines are the

building blocks of all drawings. They:

1. Convey Information:

Represent shapes, dimensions, and features of objects.

2. Define Boundaries:

Outline and separate different parts of a design.

3. Indicate Texture:

Create visual effects such as roughness or smoothness.

4. Communicate Design Intent:

Help engineers, architects, and designers share technical ideas.

5. Guide Attention: Direct the viewer's eye to focal points in a drawing or artwork.

Line conventions

Rules for Drafting Lines

·

Lines should be clear and drawn in black

or white (In CAD), depending on the background color.

·

The minimum distance between parallel

lines should ideally exceed 0.7 mm.

·

Dotted lines should ideally intersect at a

dot, while other types of lines should preferably intersect at a dash. (figure

below).

·

When two or more different types of lines

overlap or coincide, the priority for the drawing should be assigned in the

following order:

[1]

Visible outlines and edges

[2] Hidden

outlines and edges

[3] Cutting

planes

[4] Center

lines and lines of symmetry

[5] Centroidal

lines

[6] Projection

lines.

·

For instance, if a visible line overlaps

with a hidden line, only the visible line should be drawn, disregarding the

hidden line. Likewise, if a hidden line overlaps with a projection line, only

the hidden line should be drawn, ignoring the projection line.

DIMENSIONING

Dimensions are specified

on the drawing to define the size attributes, including length, width, height,

diameter, radius, angles, and the position of holes, slots, etc. These should

be directly indicated on the drawing to fully and clearly describe a component

in its final form.

Dimensioning Terminology

Dimension value

It is a numerical value

designated for the size, form, or placement of the feature. These values are

presented in a specific unit on drawings, along with the necessary details.

Dimension lines

These are thin continuous

lines indicating the dimension's direction and extent. Their distance from the

outlines should be 8 to 10 mm. Ideally the dimension values lie close to the center

of the dimension lines.

Projection lines

These are thin,

continuous lines that extend a little (2 to 3 mm) beyond the dimension lines

and should be drawn at a right angle to the feature being measured. Projection

and dimension lines should not cross each other unless it's essential. In some

instances, projection lines can be angled, but they must stay parallel to each

other.

Fig: Dimensioning terminology

Fig: Projection lines drawn obliquely

Leaders or pointer lines

These lines indicate a

feature and notes, represented by thin continuous lines. One end of the leader

terminates either in an arrowhead or a dot. The other end of the leader is

terminated in a horizontal line at the bottom level of the first or the last letter

of the note. Notes and figures are positioned above the extended dimension

lines. Leaders should not be angled at less than 30°, and they should not draw

parallel to nearby dimensions or projection lines to prevent confusion. Leaders

must never be vertical, horizontal, curved, or drawn freehand. They are

typically drawn at convenient angles of 30°, 45°, or 60°. It's best to avoid

using excessively long leaders.

Fig. Leader line (a) Correct method (b) Inclination

less than 30° is not permitted

Arrowheads

Arrowheads are commonly

used to indicate the ends of dimension lines in technical drawings. They come

in various styles, including open angles ranging from 30° to 90°, closed but

unfilled, or closed and filled, as shown in Fig. The closed and filled arrowheads,

which are favored for engineering drawings, typically have a length that is

about three times their width or depth, as depicted in Fig. For smaller

drawings, their length is generally around 3 mm, while for larger ones, it

ranges from 4 to 5 mm. In cases where space is tight and arrowheads cannot fit,

alternatives such as oblique strokes (Fig. below) or points (Fig. below) can be

utilized instead.

Fig: Arrowheads (a)

Various types (b) Closed filled type (c) Oblique stroke (d) Point

PLACEMENT OF DIMENSIONS

Aligned System

Linear dimensioning

All

dimension values are placed above the dimension lines, as shown in Fig.

These values can be read from either the bottom or the right-hand edges of the

drawing sheet. Figure emphasizes the recommended orientation for writing

dimension values on inclined dimension lines. Whenever possible, dimension

lines should be kept out of the 30º zone, which is marked by the hatched area

in Fig.

Fig. Aligned system for linear dimensioning

Angular dimensioning

Angular

dimensions and their deviations are dimensioned in the same way as linear

dimensions. Figure illustrates the preferred direction for writing the

dimension values. In some instances, dimension values can be written

horizontally, as depicted in Fig. if it enhances clarity.

Fig. Aligned system for angular dimensioning

Unidirectional System

Linear dimensioning

All

dimension values are oriented upright as illustrated in Fig. allowing them to

be read from the bottom edge of the drawing sheet. To insert a dimension value,

the dimension line is interrupted at the center. Figure shows that there are no

limitations on writing dimension values for inclined dimension lines. This

approach is beneficial for large drawings where reading dimensions from the

right-hand side can be challenging.

Fig. Unidirectional system for linear dimensioning

Angular dimensioning

Angular

dimensions and their deviations are dimensioned in the same way as linear

dimensions. Figure illustrates the proper orientation and method for writing

dimension values.

Fig. Unidirectional system for angular dimensioning

ARRANGEMENT OF DIMENSIONS

1.

Continuous or Chain Dimensioning

In

chain dimensioning, dimensions are organized so that the arrowhead of one

dimension connects directly to the arrowhead of the next, as shown in Figure

below. The overall dimension is placed outside the smaller individual

dimensions. This approach should only be used when the potential accumulation

of tolerances does not affect the functional requirements of the part. A

tolerance indicates the precision level needed in the manufacturing of the

product.

Fig. Continuous or chain dimensioning

2.

Dimensioning from a Common Feature

In

this scenario, several dimensions are measured in the same direction from a

shared feature. Clearly, all these dimensions align along a common extension

line. This arrangement is useful when dimensions need to be established from a

specific datum surface.

2.1 Progressive or parallel dimensioning

In

parallel dimensioning, the dimension lines are set up parallel to one another,

with the smallest dimension nearest to the outline. The next smallest dimension

is placed further away, followed by additional dimensions in order, as shown in

Figure below. To enhance clarity when multiple parallel dimensions are present,

they should be staggered.

Fig: Progressive or

parallel dimensioning

2.2 Superimposed running dimensioning

This is a simplified form of parallel

dimensioning, used in situations where space is limited and legibility is not

an issue. All dimensions start from a common origin, marked by a small circle

about 3 mm in diameter, and end with arrowheads indicating where each dimension

concludes. The dimension values are rotated 90° and aligned with the projection

line, as illustrated in Figure below, or positioned above the dimension line

close to the arrowhead.

Fig.

Superimposed running dimensioning

3.

Combined dimensioning

This combined dimensioning is

achieved by using chain dimensioning, parallel dimensioning, and superimposed

running dimensioning all together in one drawing, as illustrated in Figure

below.

Fig.

Combined dimensioning

4.

Coordinate dimensioning

Using

a coordinate table for dimensioning makes the drawing process easier,

especially for parts with many dimensions, since other methods can lead to a

messy look. Figure shows a plate with several holes, demonstrating that

coordinate dimensioning is the best choice, as other styles would overcrowd the

drawing. It's important to clearly mark the origin (X and Y) for the part, and

all features, like the holes, should be numbered. The coordinate table

containing the dimensional information should be placed near the title block.

Fig.

Coordinates dimensioning

SYMBOLS AND NOTES FOR

DIMENSIONING

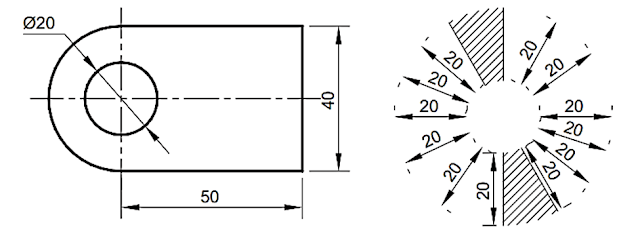

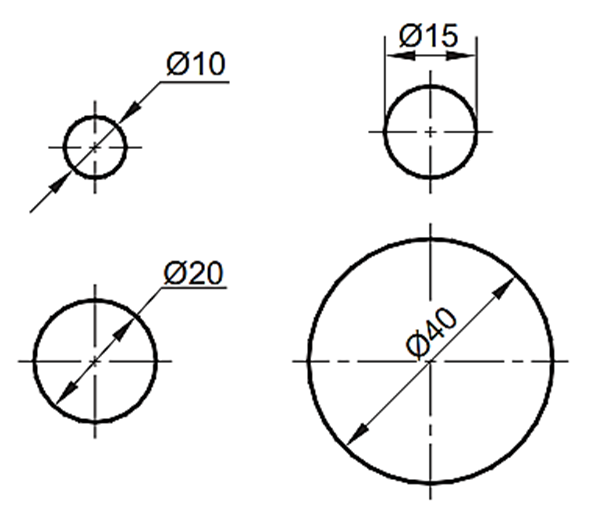

Circle

A

circle represents circular features like cylinders, holes, or series of holes

in a component, typically specified by its diameter. The dimension value should

be preceded by a symbol 'Ø', and the leader should be a radial line. Dimension

lines should be horizontal or vertical. The size of the circle and available

space dictate the method chosen. The dimension for diameter should be placed on

the most appropriate view for clarity.

Fig.

Methods of diameter dimensioning

Radius

Radius is a curved surface defined by

arcs like fillets and rounds. Its dimension value should be preceded by a

letter 'R' and specified by a leader, a radial line with one arrowhead. The

arrowhead must touch the arc contour. Alternative methods of radius

dimensioning are shown in Fig. The center of the arc should be denoted by a dot

or small cross. If space is limited, the radius's size can be determined from

other dimensioning.

Fig.

Methods of radius dimensioning

Angle

Angular

dimensions are given when a surface's outline is at an angle to horizontal,

vertical, or other radial outlines. To dimension an angle, a curved dimension

line is drawn, forming a circular arc with a center at the vertex. The radius

depends on the space required for dimension vales. Dimension values are

expressed in degrees, minutes, and seconds. Alternative methods of angle

dimensioning are also available.

Fig:

Methods of angle dimensioning

Curved surface

Curved

surfaces cannot be defined by arcs, and their contours are dimensioned using

parallel dimensioning and coordinate dimensioning, as illustrated in Figure

below.

Fig:

Curved surface dimensioning using parallel dimensioning

Fig:

Curved surface dimensioning using coordinate dimensioning

Sphere

Following

figure outlines the method for dimensioning a spherical part, specifying the

dimension value of spherical diameter by a symbol 'SØ', and the dimension value

of spherical radius by a letter 'SR'. The leader, a radial line with one

arrowhead, should be placed horizontally or vertically, and the arrowhead

should touch the arc contour.

Fig:

Dimensioning spheres

Square and hexagonal Cross section

Squares

are machined at the shaft end for turning with a spanner. The dimensioning

method for a square cross section is shown in Figure, preceded by a symbol '□'

and two diagonal lines to indicate the visible flat surface. For a hexagonal

cross section, the dimension value is preceded by a word 'HEX'. The distance

between flat faces is given a dimensional value, but the actual dimension value

represents the length of the hexagonal side. Two continuous diagonal lines are

added to indicate visible flat surfaces.

Fig:

Dimensioning of Square

cross section and Hexagonal cross section

RULES OF DIMENSIONING

[1]

The size of dimensions needs to be clear

letting people understand them in just one way. Numbers and letters should be

large enough to read. This makes sure

everyone can see and understand the dimensions without trouble.

[2]

Typically, a circle is specified using its

diameter, while an arc is defined by its radius. Center lines should not carry

over from one view to another.

[3]

Projection lines are typically drawn at a

right angle to the feature being dimensioned, but they can also be drawn at an

angle, provided they remain parallel to one another.

[4]

Dimension values should ideally be

positioned near the center of the dimension line. If space constraints make

this impossible, they can be placed above the extended part of the dimension

line beyond the arrowheads, preferably on the right-hand side.

Fig: Correct Placing dimension 5 and

10

[5]

Whenever possible, dimensions should be

placed outside the views. If necessary, they may be positioned within the view,

as illustrated in Figure below. However, dimensions should only be placed

within a view if it enhances the clarity of the drawing.

Fig:

Placing dimension

[6]

The lines in a drawing should never act as

dimension lines or intersect with them. Dimension lines need to be consistently

spaced throughout the drawing, placed 8 to 10 mm away from the object's edge

and 6 to 10 mm apart from each other.

Fig: Placing dimension

[7] When there are multiple parallel dimensions, they should be arranged in a staggered manner.

[8]

Dimensions should be added to the view

that best illustrates the corresponding features.

[9]

Dimensions provided in one view do not

need to be repeated in another, unless necessary for identification, clarity,

or both.

Fig. Placing dimension

[10]

Dimensions should be added to the view

that best represents the contour shape. They should reference visible outlines

instead of hidden lines. Dimensions should originate from a baseline,

centerline of a hole, cylindrical parts, or finished surfaces—elements that can

be easily identified and are aligned with design requirements and relationships

to other components, as illustrated in Figure below.

Fig. Placing dimension

[11]

An axis or contour line shouldn't be used

as a dimension line; however, it can serve as a projection line.

Fig. Placing dimension

[12]

Whenever possible, the intersection of

dimension lines should be prevented. However, if two-dimension lines must

intersect, they should remain unbroken.

[13]

When multiple dimensions are placed on the

same side of the drawing, position the shortest dimension closest to the

component. This helps prevent dimension lines from crossing projection lines.

If their intersection cannot be avoided, neither of the lines should be shown

with a break.

Fig: Intersection of projection and

dimension lines is unavoidable

[14]

Overall dimensions should be placed

outside of the intermediate dimensions. If an overall dimension is provided,

one of the intermediate dimensions becomes unnecessary and should not be

included.

Fig.

Dimension placing

[15]

If there is enough space for the arrowhead

termination, it should be placed within the dimension lines' limits. If space

is limited, the arrowhead termination can be shown outside the intended

dimension line limits. However, if the space is too small for an arrowhead, it

may be replaced with an oblique stroke or a dot.

Fig.

Methods for arrowhead termination

[16]

Whenever possible, all dimensions in a

single drawing should be represented using a single unit of measurement. If a

drawing uses different unit a footnote is added in a prominent location to

clarify the unit of measurement.

[17]

When a dimension line cannot be fully

extended to its usual endpoint, the open end should be marked with a double

arrowhead.

Fig. Free end is terminated with double arrowheads